By Peter Jenkins

One of the items I've been working on this term is a metal strong box. The box in question can be seen below before treatment, and one can see that it has been forced open and broken into. Although this caused issues in conserving the box, it made making the key for it (on which this post will focus) a lot easier.

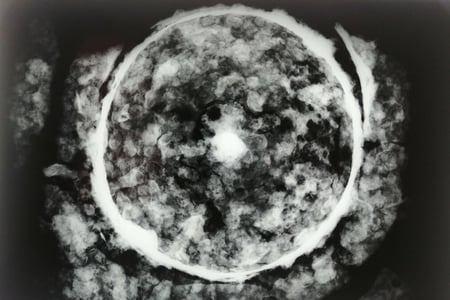

Thanks to the box being already open, I didn't have to worry about picking the lock, and was able to simply remove the whole lock plate, giving me excellent access to its inner workings, which looked like this:

Although this initially appeared complicated and confusing, after around half an hour of conservation-level physical interaction (tinkering) it became clear that the only parts actually damaged were the bolts that were bent out of place at the top, and that the real task would be making the key. My first step for this was to make a test key.

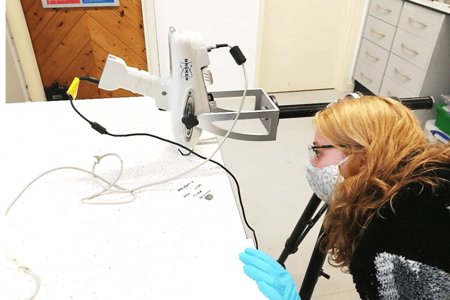

It may not be pretty, but it does the job! And more importantly, gave me a better understanding of the lock, and allowed for a template of the bit to be made, so when I came to making the real thing, the chances of going wrong were limited. But how did I come about making such a wonderful proto-key? Initially I removed the levers (the parts of the lock that move up and down to allow the bolt to slide) from the rest of the mechanism, as can be seen below.

This gave me a chance to make repairs to the bolt and give it a good clean. Having done this, I then replaced the bolt, and one of the levers, and made a key that worked with one, by filling out the relevant section on the blank bit. I then added the next lever, and did the same, and so forth. Having made my proto-key, I could then research and think about designs for the new key. After many hours of library and internet research, all the evidence suggested my box's key would look like…..a key. It seems like with strong boxes in the 1800s of this style, there wasn't a great deal of decoration being applied, but I did find several examples of the stem of the key being decoratively turned on a lathe, and so jumped on this opportunity to give my key a bit of life. The turned-down stem looks as follows:

As you can see, it's a pretty wild design! You can also see the new bit in the background, but to give you a better view, see below

It's worth pointing out here, that although this key is a relatively simple design, it still took a considerable amount of time to get it correct, which gives us an idea of how much time, effort and skill was put in by the original crafts folk to make keys like this, and others far more complicated.

The next step, and possibly the most infuriating was to stick the bit and the stem together. Although the proto-key was welded, a more historically accurate method was necessary for the real thing, so brazing was chosen (and also because I love brazing). The bit of the key had to be bound in place to the stem and kept in the correct position. This is easier said than done. So after around 45 minutes of intense concentration, and with the aid of a few rude words, the bit was held in place and ready to braze! (You may notice the poor focus in the below picture, please excuse this, as it was due to the aforementioned frustration!)

So once the bit was brazed on and I checked that it worked (below) it was time to make the bow.

The bow is the section of the key at the end opposite to the bit…the bit's the bit you put in to the key hole. I tend to think of the bow as the "handle" of the key. After consulting with my research, it seemed that other boxes of this style had a simple "O" bow which looked a bit like this:

(It didn't look like that, but if I show you it now it'll spoil the big finale!)

I foolishly thought that making a simple "O" wouldn't be too much of a problem-I was wrong. The issue arose when I realised that the "O" that I'd marked to cut out with a piercing saw was being removed when it came to drilling the inside of the "O" out, and if I cut out the "O" first, then there was no material to clamp it down when it came to drilling the middle out. Needless to say, a great amount of time and frustration went into what should have been a simple task! Below is a picture of the fifth(?) attempt.

However, I eventually managed to get it right:

And hastily brazed the bow on, which looked like this:

At this stage it still needs to be coloured and aged down, so I'll probably put up a picture of it when that's done, but this is it for now, and most importantly, it looks like a key! The morals of this story are: A. plan ahead, B. don't underestimate how fiddly and complicated something relatively simple looking can be, and C. remember how much time and how hard craftspeople before us worked!